Sewer Cleaning as an Essential Part of Wastewater Management

Sewer cleaning is a crucial factor in wastewater management and indispensable for the functionality and longevity of wastewater systems. Deposits that form in the pipelines can arise due to various factors such as changes in gradient or insufficient drainage conditions. These deposits consist of coarse and solid materials, containing both inorganic and organic components.

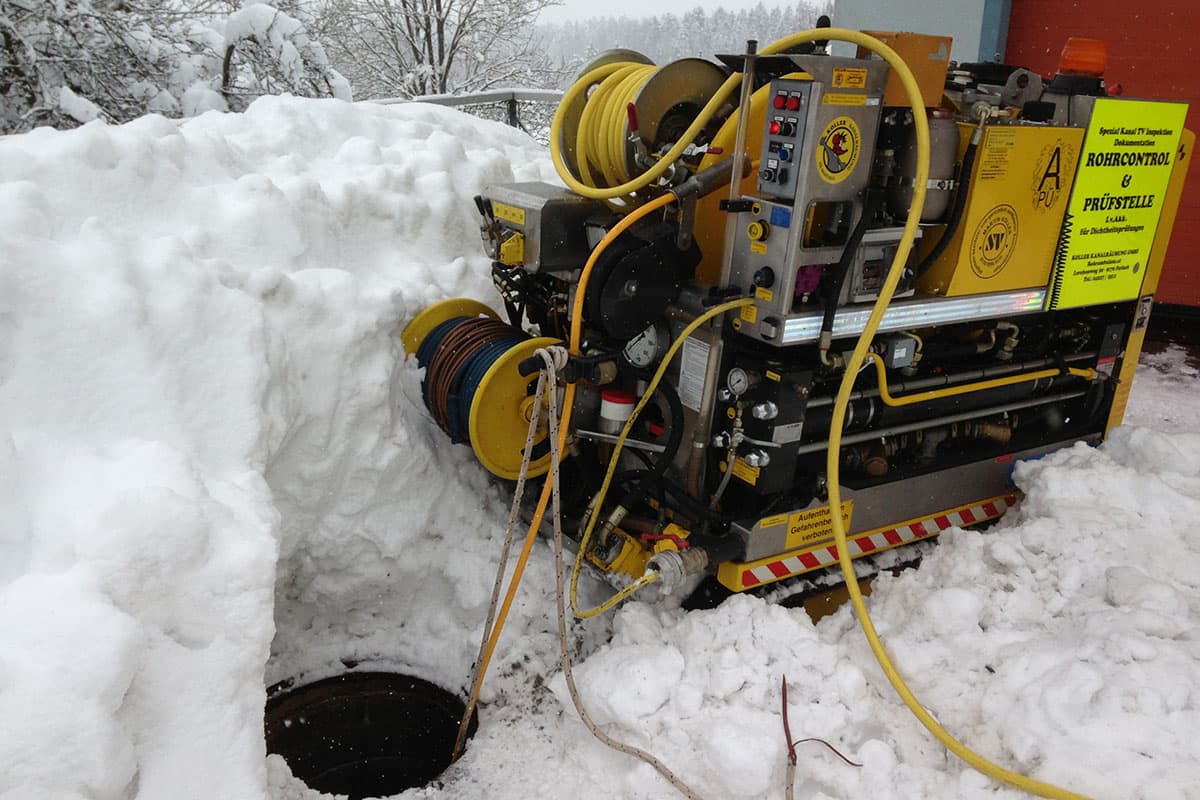

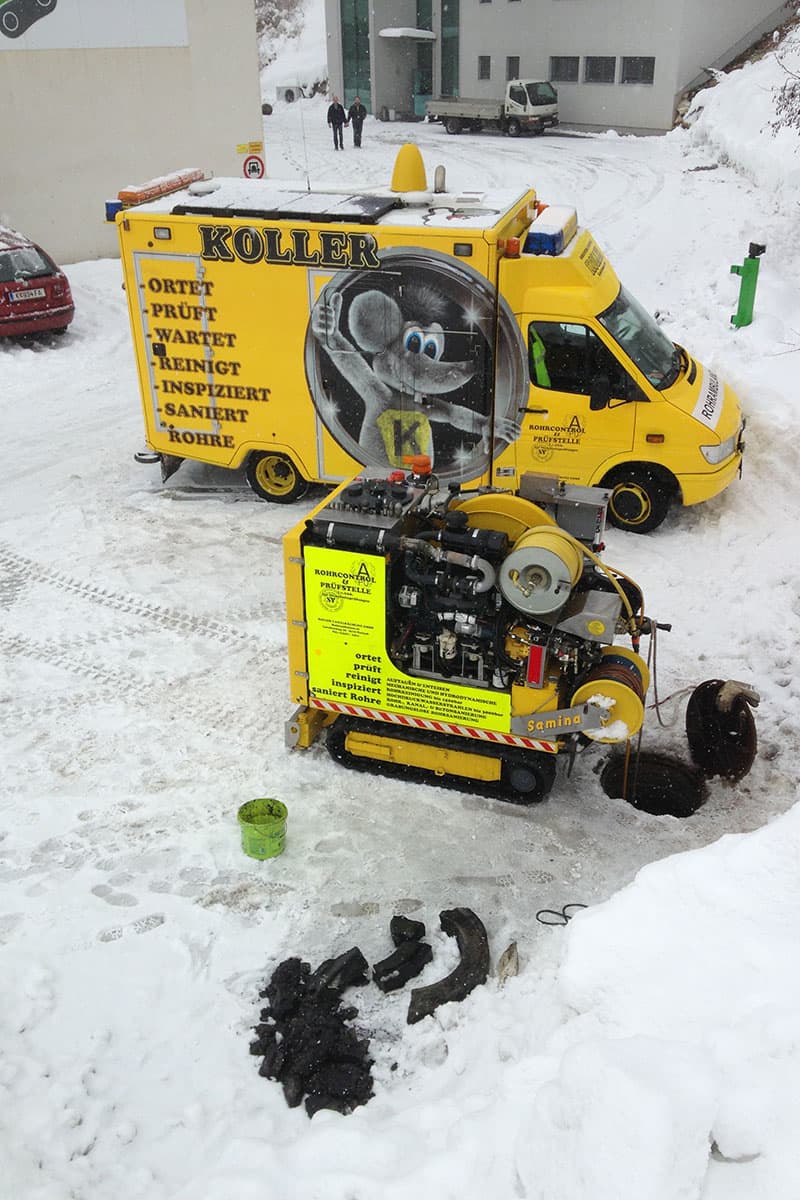

To ensure the functionality of the wastewater system and avoid serious problems such as backups or blockages, Koller Kanalräumung GmbH relies on regular and thorough sewer cleaning. This is essential to detect and remove deposits in the pipelines early.

In this context, environmentally friendly techniques and preventive measures are of great importance to improve water quality and ensure the longevity of the infrastructure. The following sections highlight the causes of deposits, the importance of sewer cleaning, and innovative and sustainable cleaning techniques.

Deposits in Wastewater: Causes and Challenges

The formation of deposits in the wastewater system can be influenced by various factors. These include, among others, changes in gradient or drainage conditions. A common cause is the insufficient carrying capacity of the wastewater, which is not enough to keep the pipelines clear. This leads to the accumulation of sewer debris, a mixture of grease, sand, gravel, and lime residues. Such deposits can cause serious problems such as backups or blockages.

Additionally, there are drainage obstructions that arise from root growth, negligent construction measures, or improper rehabilitations. These obstructions can damage the pipelines and narrow their diameter, further impairing drainage capacity. Faulty pipe installations can also lead to deposits such as concrete and lime encrustations adhering to the inner walls of the pipes, significantly impairing the functionality of the wastewater system over time.

Importance of Sewer Cleaning

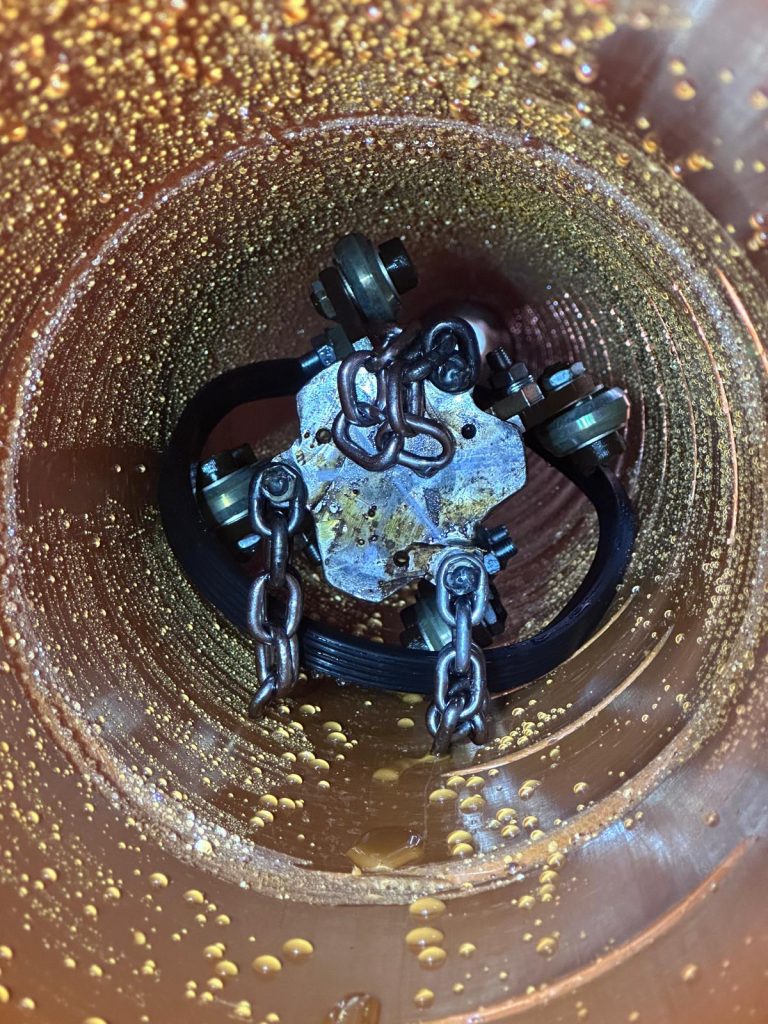

For effective sewer cleaning, it is crucial to thoroughly remove the bottom deposits. This usually requires several work steps and comprehensive cleaning of the entire pipe cross-section. Special cleaning nozzles are often used, including rotary, milling, and vibrating nozzles. The choice of methods depends on the specific conditions and the planned rehabilitation procedure.

Before the rehabilitation process, it is essential that the pipe walls are completely clean and grease-free. In some cases, the use of hot water or special cleaning additives may be necessary. For certain procedures, such as high-pressure water jet cleaning (HDWS), we use pressures from 500 to 3000 bar, depending on the desired cleaning objective, to efficiently remove the deposits.

Sustainable Approaches in Sewer Cleaning

Koller Kanalräumung GmbH places a special focus on environmentally friendly techniques and procedures for sewer cleaning. This includes the use of high-pressure cleaning methods that do not require chemical additives. Innovative methods, such as the use of biological cleaning agents, are also gaining increasing importance.

Regular maintenance and inspections of the sewers are crucial to detect and remove deposits early, before they lead to larger problems. Through preventive measures, we not only increase the lifespan of the infrastructure but also protect the environment and improve water quality in wastewater treatment plants.

Special Cleaning and Special Techniques

The term “special cleaning” refers to the cleaning of special profiles, large pipes, shafts, basins, tanks, and other structures that place special demands on cleaning technology. Specialized cleaning tools such as bottom cleaning nozzles, hand guns, propeller nozzles, and injectors are used here. In some cases, an optimized guide roller can also be used to increase cleaning efficiency.

Thanks to our many years of experience in sewer cleaning, we are able to master even complex challenges and offer customized solutions. An example of such cleaning work can be found at the main wastewater treatment plant of the provincial capital Klagenfurt. Here, suction and hydrodynamic high-pressure cleaning work was carried out on the secondary clarifiers. Approximately 500 m³ of sludge, grease, and shell lime were removed from a depth of over 12 meters. The daily output was between 100 and 130 m³, including all transport, emptying, and cleaning times.

Furthermore, high-pressure cleaning work is also carried out on aeration tanks to remove deposits on the aerators, especially those caused by shell lime.

Conclusion

The challenges of sewer cleaning are diverse and require a holistic and sustainable approach. Through regular maintenance, innovative cleaning techniques, and careful planning, deposits can be effectively addressed and the functionality of the wastewater system ensured long-term. This not only contributes to the preservation of the infrastructure but also protects the environment and improves water quality in wastewater treatment plants.

Sewer Pipe Inspection for the State Testing Institute tgm and mta-messtechnik.at

- Product Standard AGRE Guidelines

- Test Pressure 200 Bar

- 50 cycles at 2 minutes each Manufacturer Martoni / Pipes are installed in the Brenner Tunnel