Special Applications Such as Milling out Incrustations or Solidified Deposits / Removal Using the Hydrodynamic Pipe Cleaning Method

With high-pressure water jet technology, we can perform a variety of tasks many times faster, cleaner, and more economically.

We apply high pressure from the smallest pipes up to and including walk-in sewers. Depending on the desired cleaning result, we work with pressures and water lines between 250 to 1500 bar, which corresponds to speeds of 200m/s to 600m/s (600-2000km/h) at the nozzle exit.

Changes in gradient or drainage conditions (water flow, pipe diameter, profile shape, etc.) lead to the deposition of coarse and solid materials contained in wastewater, which are of inorganic and organic origin. Since the carrying capacity of the wastewater alone is often insufficient to keep the pipelines clear, sewer debris consisting of grease, sand, gravel, and lime residues accumulates. Such deposits lead to backflow or blockages.

High-pressure cleaning is categorized into the following 3 points

- Hydrodynamic high-pressure cleaning in all types of lines

- Preparations for rehabilitation

- Surface cleaning/Tank cleaning, Demarking

Water jet high-pressure technology is used by us in both drinking water pipes and wastewater pipes and is excellently suited for the following tasks:

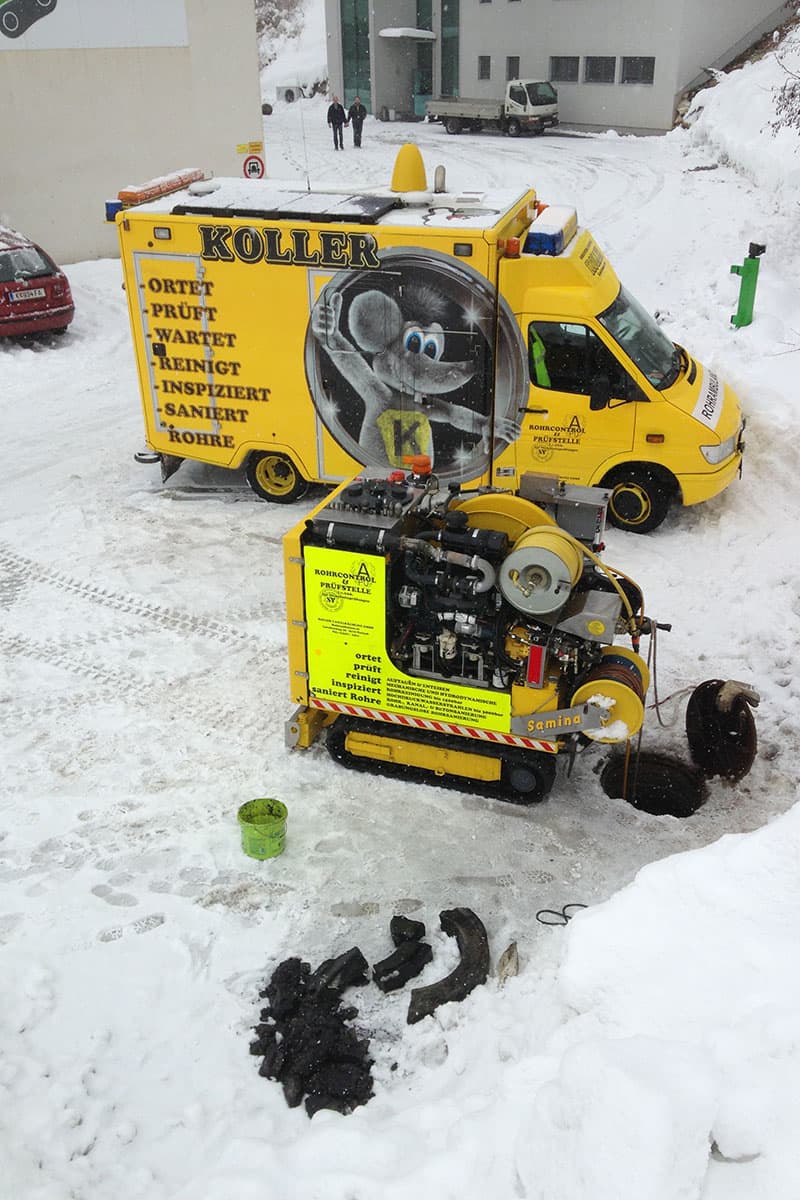

Below you can see some pictures of our cleaning successes:

Removal of algae/mussels from a jetty to ensure safe boarding/disembarking for bathers again. Our emission-free high-pressure sprayer with a pumping capacity of up to 600 bar is particularly suitable for this, allowing clean, quiet, and efficient work without causing damage to the sunbathing lawn.

In preparation for rehabilitation, high-pressure water jetting is used by us in the following areas.

- Preparation for manhole rehabilitation

- Roughening concrete substrates to ensure better adhesion

- Removing weathered concrete layers; high-pressure water jetting preserves the intact substrate.

- Exposing reinforcements

With our hydrodynamic high-pressure cleaning methods, we can remove stubborn dirt and paint residues from almost all surfaces.

These include:

- Removal of moss, algae, mold, and grease from all concrete, paved, or natural stone surfaces

- Cleaning of drinking water reservoirs

- Debarking tree stumps

- Roughening surfaces/increasing friction coefficient

- Removal of paints, resins, rubber abrasion, silicones, and greases

- Paint stripping, Coating removal, Rust removal

Due to deposits in the wastewater channels, putrefaction processes already occur within the pipes. The resulting by-products lead to an unfavorable change in wastewater quality (complicated wastewater treatment in the sewage treatment plant and odor problems), sometimes causing damage to the building substance (sulfuric acid corrosion), thus shortening the lifespan of valuable sewer structures.

Tank and basin cleaning for revision at the Klagenfugenfurt sewage treatment plant: Removal of compacted deposits, grease incrustations, MAP (Magnesium Ammonium Phosphate MgNH4PO4). The challenge with this task is to perform the basin cleaning as effectively and material-friendly as possible; for this, we work with different pressures and tools depending on the deposit.

High-pressure water jetting with a special propeller nozzle with electromagnetic brake for inspection preparation – Manhole scan 4K360