Soak Pits, Infiltration Shafts, Infiltration Systems, Trickling Filters, Drainage Systems, Wells

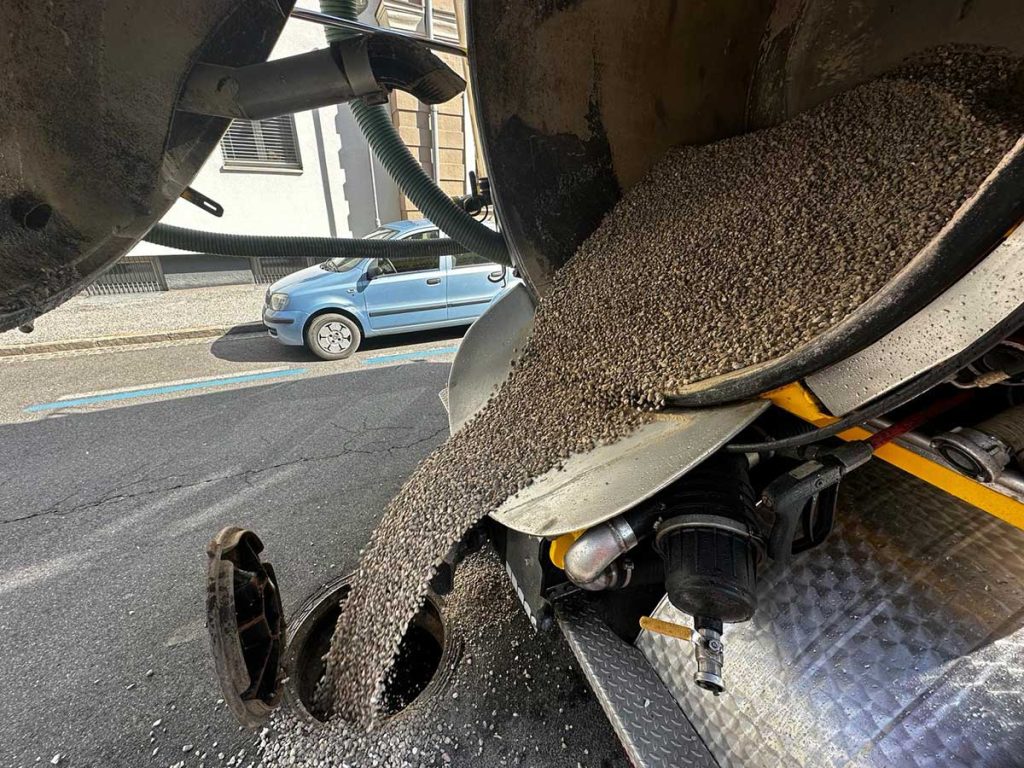

Our combined special high-pressure flushing and suction vehicles can empty, clean, and refill the aforementioned systems in one go. Thanks to suitable, variable tank chambers and separation devices, tasks such as excavation, sludge suction, and the collection of gravel and crushed stone – both dry and wet – can be carried out using various suction pipes. Afterwards, these materials can either be blown or discharged.

Preventive Cleaning and Rehabilitation of Infiltration Systems

In rare cases, infiltration systems are cleaned preventively. For silted-up soak pits, measures are often only taken when there is a backflow and a pipe blockage is being searched for. However, if a backflow is detected due to the infiltration system, it is often recommended to rebuild the system, without considering that a much more cost-effective, faster, and environmentally friendly infiltration system rehabilitation would be possible through us.

Hydrodynamic Drilling Lances in Subsurface Cleaning

For subsurface cleaning, we rely on hydrodynamic drilling lances to clean the silted-up ground. The high-pressure equipment used in this process extracts and loosens the fine particles from the ground, while simultaneously sucking them out and transporting them into the suction tank.

Depending on the work required, the system is then filled by us with washed filter gravel. This is either blown in, flushed in, or tipped in.

The flushing out and suctioning of fine particles is carried out with suction excavators. Sludge layers 2–4 m deep are not uncommon. These consist of dust, leaves, and waste of all kinds and, over time, lead to increasingly poor infiltration of the introduced wastewater.

Suctioning of the Filter Bed or Sludge Layer in the Base Area

When suctioning the sludge, high-pressure technology and so-called drilling lances are used to flush out the remaining fine particles in the subsoil. If the cleaning success is not yet visible, further penetration into the ground can be done (while paying attention to the system’s support). If it is necessary to penetrate under the concrete rings of the infiltration system, we reintroduce filter gravel into the infiltration system to prevent settlements and damage to the roadway. We also facilitate future cleaning of the infiltration system, as the original soil will not become silted up.

After all Sludge Components Have been Washed out of the Ground, a Functioning Infiltration Can be Immediately Detected with the Drilling Lances (Water Discharge: 250 L/Min at 300 Bar).

We also offer the cleaning of coalescence filter systems or adsorption infiltration shafts, which are prescribed by the water authority for contaminated stormwater from traffic areas. Due to the activated carbon mats in these systems, an increased cleaning interval is required. It is important that a sludge trap is provided during the construction of such a system to minimize contamination of the filter mat.

We Would be Happy to Propose a Maintenance Contract for the Regular Emptying of the Sludge Trap and the Hydrodynamic Cleaning of the Filter Mat in the Adsorption Shaft, in Order to Extend the Lifespan of the Filter Mats and Prevent Costly Replacement.

Maintenance Cleaning of Infiltration Systems with Coalescence Filters

If the coalescence filter mat is too heavily contaminated, the coalescence filters with activated carbon are replaced, whereby we safely retrieve the filter with a winch (approx. 300 kg). After the replacement, new coalescence filters with activated carbon (FB SWUmwelttechnik DN2500) are installed and secured.

For the cleaning of contaminated traffic areas and stormwater, we use SW-Adsorption Infiltration Shafts AQUAfilt with activated carbon mats. These filters consist of a combination of high-quality mineral substrates with adsorptive properties and pH buffering capacity. They are particularly effective in reducing heavy metals (copper, cadmium, zinc) as well as hydrocarbons (HCs) and PAHs (polycyclic aromatic hydrocarbons). Many other pollutants are also significantly reduced.