ABOUT OUR COMPANY

KOLLER Kanalräumung GmbH is one of the oldest family businesses in the sewer cleaning industry in Austria.

For 4 generations, the company, which has always had to adapt to difficult economic conditions, has been managed by direct successors of the company founder Koller Josef, established in 1908.

Koller Josef 1908

Koller Martin 1947

The Koller family’s estate, VLG. PETRITSCHE – Petritschhube in Dollich 6, first mentioned in 1582 (Carinthian Provincial Archives), has been continuously operating agriculture for over 450 years through 12 generations.

Further business areas of the KOLLER company include the planning, development, and production of special vehicles for sewer and pipe inspection, high-pressure water jet flushing vehicles, up to combined sewer inspection and rehabilitation vehicles, including their associated equipment.

KOLLER special vehicle superstructures are high-quality, economical, durable, and unique custom builds. They are ideally suited for emptying and cleaning all facilities in water supply and disposal, as well as for transporting and conveying solids – from wet to dry. The vehicles clean quickly, cleanly, effectively, environmentally friendly, and hydrodynamically with high-pressure water.

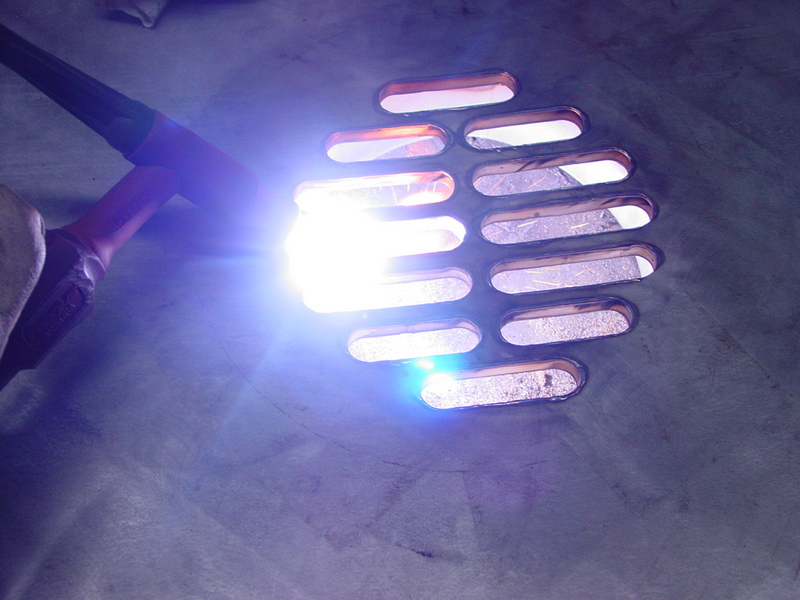

Production of a super-light manhole cover (up to 250 KN) in stainless steel design with a central floor drain and odor trap.

With J-Copter GmbH, another business segment has grown. This includes the manufacturing, development, and production of air sports equipment/aircraft, specifically gyrocopters up to 560kg, as well as sales and rental.

The company’s headquarters are located at the southernmost point of Austria, in the middle of the Rosental valley, close to Slovenia and Italy. The scope of operations and services extends to Northern Italy, Slovenia, Croatia, and throughout Austria.

Our superstructures are specially adapted to our customers’ wishes and therefore offer more possibilities to solve customer problems than conventional standard vehicles. For our own superstructures, we are not tied to manufacturers who offer complete solutions, and can therefore develop special or prototype superstructures down to the last detail, as we can select the best in its class for each product.

Our contacts through four generations allow us to create even more ingenious solutions in terms of construction technology, quality, and customer-friendliness compared to other manufacturers.

Some Outstanding Examples:

- Superstructures without subframes (weight savings, lower body height, better road holding due to lower center of gravity),

- All our vehicles are equipped with self-propelled inspection cameras. This means no second vehicle is needed to perform a sewer inspection with documentation.

- 2 sewer flushing pumps mounted on the vehicle: 1x high-pressure pump up to 300 bar at 280 l/min, 1x ultra-high-pressure pump up to 1500 bar at 30 l/min. Optimal utilization of auxiliary drives (no wasted space in the tank area).

- Shortest possible wheelbase while maintaining the chassis’ center of gravity (axle load distribution through variable chamber division), long suction lines, large volume for accessories, driver-friendly control, forward-looking planning for durable superstructures (service life of almost 50 years).

- Tank construction with 4mm wall thickness in stainless steel (standard for competitors is 5, 6, and 8mm), many stiffening rings, self-supporting construction, three-point suspension, oversized tilting hinges.

For example: a trenchless manhole frame rehabilitation system. Koller Martin, originator and manufacturer of the Horizontal Cutting Device for GLOBAL Schachtrahmen Sanierung und Dienstleistungs GmbH.

All special vehicles (sewer flushing vehicles, machines, and equipment) used by us originate from our own idea and production workshop.