Rehabilitation of Pipes, Shafts, or Structures

In principle, it is possible to rehabilitate all types of pipelines and structures continuously (inliner) or section by section (point liner) without excavation, even when groundwater is already present. However, the best and most cost-effective type of rehabilitation can only be determined for a specific project, which usually requires some preparation time. This rehabilitation measure can be carried out immediately after a defect is detected, if necessary, preventing additional costs due to delays in construction acceptance. With this method, it is also not necessary to take the pipelines out of service. Water flow is maintained during the rehabilitation work, thus avoiding costly pumping. After the rehabilitation is completed, a new leak test can be performed, providing proof of the structurally sound condition.

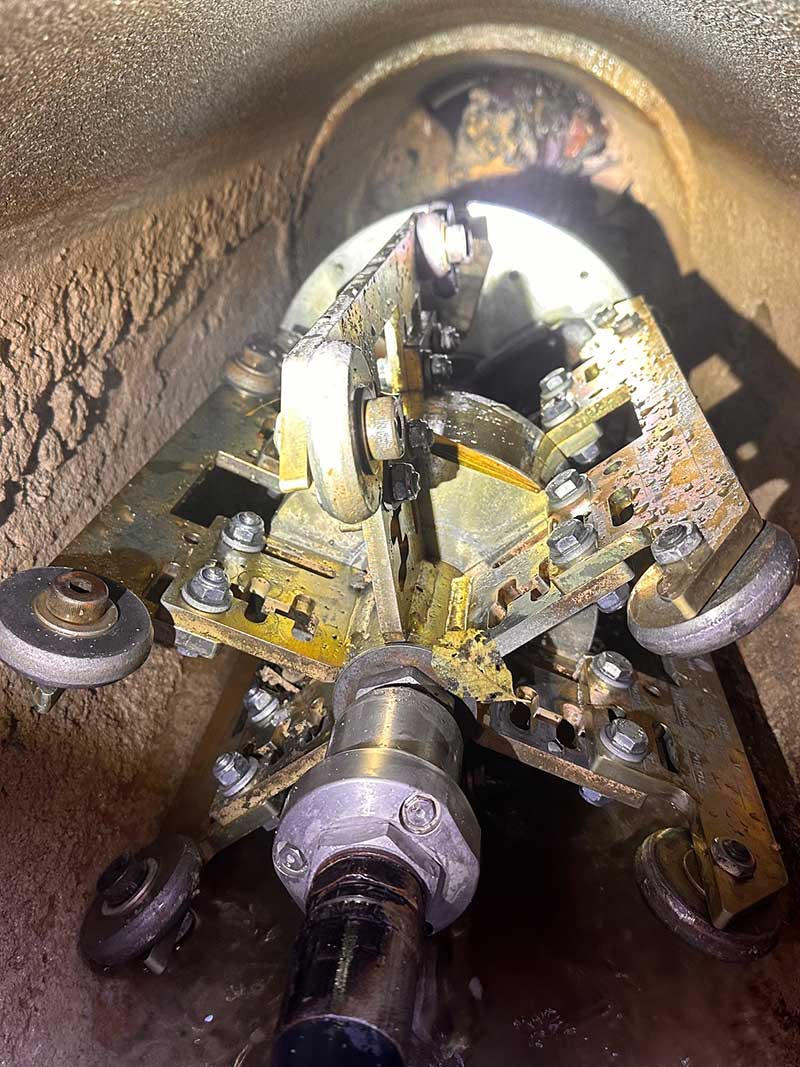

Pointliner

A method for pipe or sewer repairs for localized damage in pipelines. With the Point-Short Liner, pipe damage such as pipe breakage, root intrusion, misaligned joints, shard formation, or even strong infiltration (foreign water ingress) can be easily rehabilitated.

Advantages of the Point or Short Liner

- Safe

- Durable

- Cost-effective

- Simple

- High-quality

Material Description:

Trenchless pipe rehabilitation using ECR fiberglass Pointliner Advantex® DN 80-1200mm with 5-12mm wall thicknesses, lengths from 0.2m to 3m, impregnated with non-foaming, elasticizing three-component resin with good adhesion even on damp surfaces Easy PUR plus. 2- or 3-component reaction plastics based on silicate resin, specially developed for sewer rehabilitation for partial repairs, or complex material in hose form consisting of ECR glass surfaces with polyester core material. The hose seam with overlap ensures consistent pipe properties over the full circumference. Heavy longitudinal glass reinforcement ensures consistent length when pulling in the material. It prevents the material from stretching or tearing during installation. A bonded hose seam means no visible seam in the finished pipe.

Diameters from 150mm – 1100mm with wall thicknesses from 2mm – 9mm are possible. Special requests can be accommodated. The sizing on the fiberglass is compatible with polyester-vinyl ester and epoxy systems.

Large Profile Inliner

Inliner pipes with subsequent annular space filling approx. 290 linear meters

Due to its underground execution, the MCS-Inliner® technology spares residents from dust, noise, and traffic jams and, thanks to its high social compatibility, eases the burden on authorities when carrying out large projects in sensitive urban areas. More info at:

www.angerlehner.at/deutsch/pages/dkanal.html

If necessary, the sewer is milled to remove contaminated material or to enlarge the cross-section. Subsequently, GRP profiles are inserted, and the annular gap is filled with special mortar. The result is equivalent to a new sewer and is statically self-supporting. Thanks to the globally unique MCS-Inliner® milling technology, the flow capacity is increased compared to conventional methods.

Example of successful preparation for large profile inliner rehabilitation Feldkirchnerstraße 9020 Klagenfurt/ GRP egg profile DN 900/600

Inliner

Advantages:

- Minimal site setup

- High cost-effectiveness

- Proven rehabilitation materials

- With all test certificates

Areas of application:

Main lines and connections

Sewers, DN80 to DN 600mm

Complete pipe lengths including bends, pipe sections, and nominal diameter changes

PL-Fiberglass Inliner:

Product Description:

The hose described here is intended for the repair of non-pressure pipes in municipal and industrial areas. The flexible reinforcement is used in conjunction with thermosetting synthetic resins to repair damaged pipes, with the impregnated hose being pulled into the pipe and cured by steam.

PROPERTIES:

Complex material in hose form consisting of ECR glass surfaces with polyester core material. The hose seam with overlap ensures consistent pipe properties over the full circumference. Heavy longitudinal glass reinforcement ensures consistent length when pulling in the material. It prevents the material from stretching or tearing during installation. A bonded hose seam means no visible seam in the finished pipe. Diameters from 150 mm – 1100 mm with wall thicknesses from 2 mm – 9 mm are possible. Special requests can be accommodated. The sizing on the fiberglass is compatible with polyester-vinyl ester and epoxy systems. The material can also be supplied flat with widths up to 3.5 m.

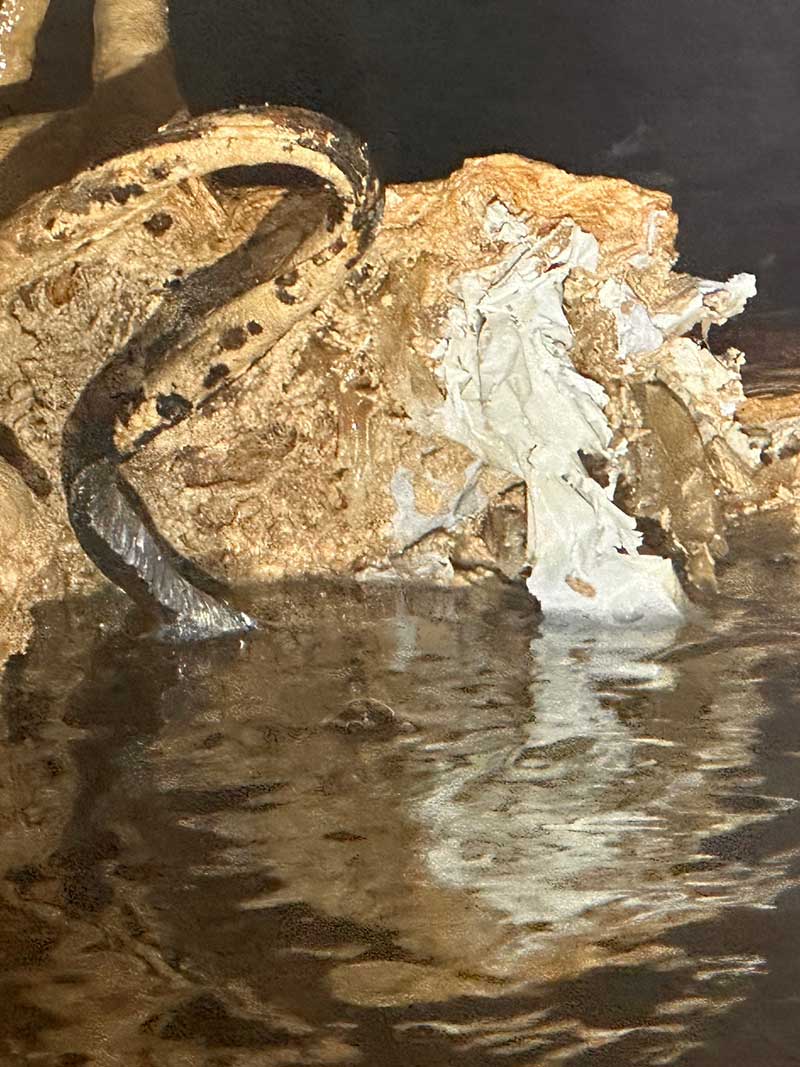

Before

After

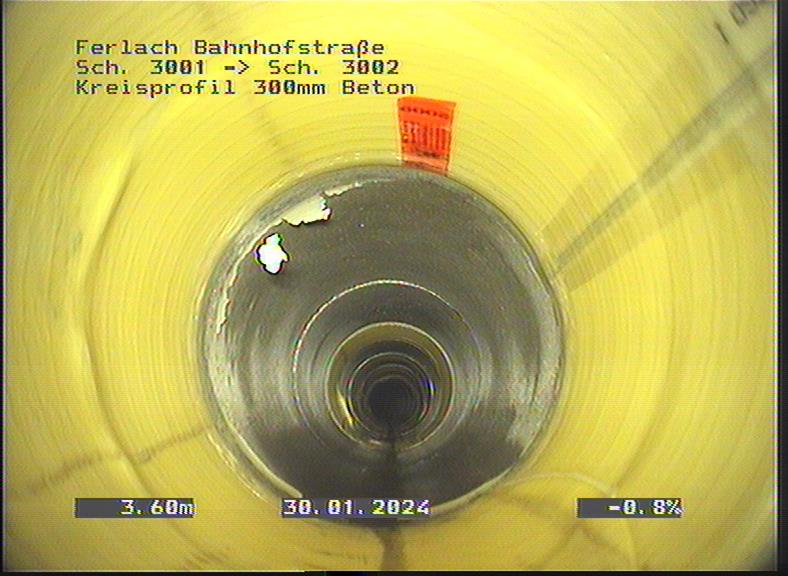

After

After

Technical Data:

The material properties were measured on a fully cured pipe. They are largely dependent on the resin used and the impregnation method. When fully impregnated and cured with polyester resins, the following values are obtained:

Tensile Strength ASTM D638

6.4 x 10 kPa

Modulus of Elasticity ASTM D790

8.3 x 10 kPa

Flexural Strength ASTM D790

1.8 x 10 kPa

Barcol Hardness ASTM D2583

60

Weight

500 g/m² – 2,200 g/m²

Thickness

2 mm – 9 mm

Glass Content

45% – 65%

Hose Diameter 150 mm – 1,100 mm

Examples of work performed in trenchless rehabilitation